Integrating Parallel Pipes will empower your simulation team by drastically simplifying reporting

Partnered with

.png?width=2000&height=1125&name=Untitled%20design%20(3).png)

Engineers spend 17.5% of their time gathering and sharing findings

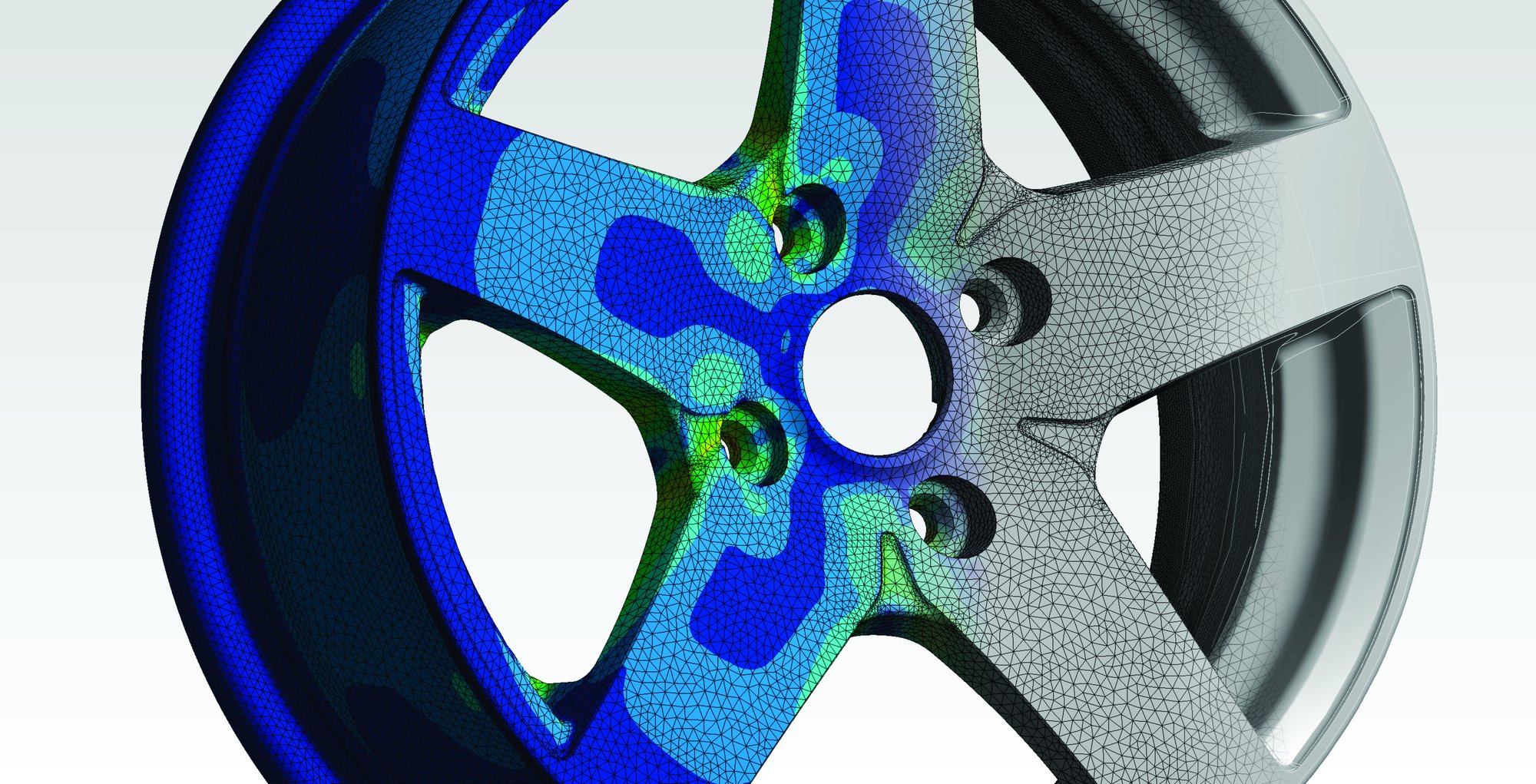

Made for Simulation-Driven Teams

Analysis is hard enough, let us take the time-consuming parts off your hands

Workflow Optimization

- Recapture hours of analysts' time

- Inform design in a fraction of the time

- Keep engineers on high-value tasks

Easy Integration

- Maintain current solutions and processes

- Accepts all major simulation solution file types

- Automates manual cut and paste processes

Recapture time spent on Reporting & Documentation

- Minimize field issues

- Understand performance

- Eliminate rework

"With Parallel Pipes, we understood how to best improve our product. The platform gave our engineers clarity, and was easier to use compared to other software tools."

Meet the Team

Our team is built with a core background in computational physics with focus on artificial intelligence, material science, and mechanical design. Learn more about us and feel free to reach out, we are excited to meet you. If you'd like to stay up to date on our progress, sign up for our newsletter.

Contact us

We look forward to bringing your engineering team and development cycle to the next level, connect with us here.

.png?width=1563&height=1563&name=Parallel%20Pipes%20(2).png)